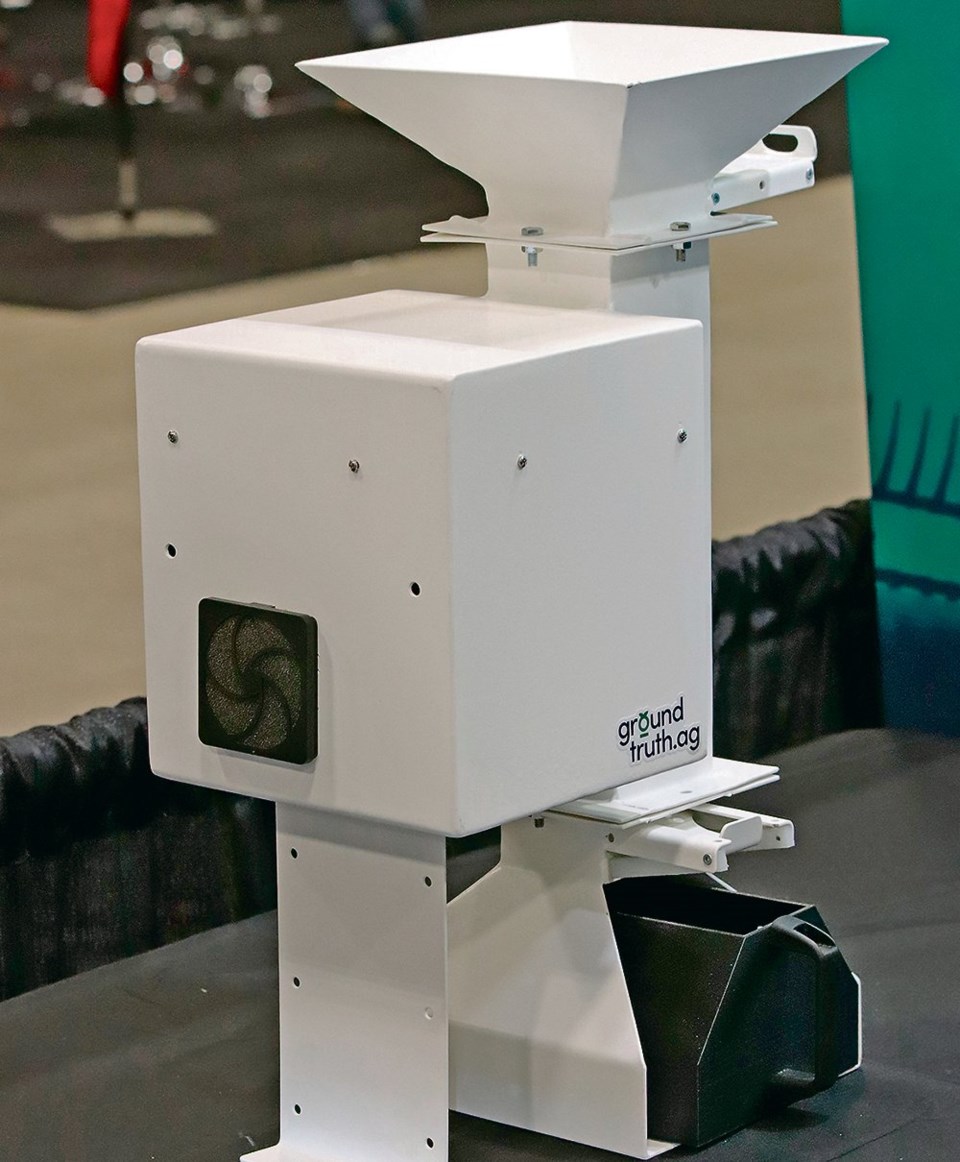

REGINA — A desktop grain tester that uses machine vision to determine grain grades was on display at a recent farm show in Regina.

“We’re building a unit that will go on the combine and will be able to grade grain quality in real time as you harvest. But as part of the journey, we’ve also built a bench-top version of that, and that’s what we’re providing a sneak peek into here at the farm show,” said Kyle Folk, chief executive officer of Regina based Ground Truth Ag.

Ground Truth Ag was one of 16 companies to pitch their products at the AgTech Accelerator at Canada’s Farm Show, held June 20-22.

In 2011, Folk started IntraGrain Technologies, which produced Bin Sense, which was later acquired by the Calian Group in 2018.

He said to determine the grain quality there are visual and non-visual characteristics that must be assessed.

“For the visual characteristics, we use machine vision. We have a camera that takes pictures of the grain and then we have models that run in the background that identify those characteristics that are showing up, that have damage or disease or anything that’s going to negatively impact that quality,” Folk said.

“If there is ergot present, sclerotinia, fusarium, immature frost, heat stress. We started with (Canadian Western red spring wheat) because it’s actually the most difficult to grade of all the grains. There are quite a few different things that could be wrong with it, mildew is another one.”

The process of training algorithms to identify specific characteristics of the grain is tedious. Damaged grain is identified and scanned over and over and eventually the company will iterate models capable of predictions and identification of damaged grain without assistance.

Once one parameter is trained into the algorithm, the team moves on to teach it how to identify a different characteristic.

“The goal for us is to be able to determine grade, and so to be able to determine grade you have to be able to identify all of the quality factors,” Folk said.

With the desktop sampler, the user sets the number of images it will take of the sample and the system will take about 30 seconds to provide results.

Near infrared spectroscopy will predict the value of non-visual grain characteristics in future products, including moisture and protein content, but this feature is not yet available in the desktop unit.

Folk said testing grain with desktop samplers doesn’t provide a representative sample of a grower’s grain inventory. He said the sampler Ground Truth Ag is developing, which is expected to be installed in combines, will be better at this.

“It will be taking continuous samples at intervals, of say, every minute or every two minutes, where we’ll be pulling a sample through imaging and scanning and then letting it back with the rest of the grain. It will do the same thing over and over and over as you’re driving on your combine,” Folk said.

He said connecting this technology to software farmers are familiar with is key.

“We understand that data fatigue for farmers is a real thing, and so being able to API (application programming interface) our information across to other platforms that farmers are using is a priority for us and we’re building that into the software side,” Folk said.

The Ground Truth Ag combine sampler can help growers segregate or blend their grain, but one of the most important uses for it is that it can give users a better understanding of the product they have.

“Getting told what you have for quality based on a small sample that you send in never gives much of a position of confidence when it comes to marketing your grain. It gets tested again when you deliver it, and it may be different from what you were told from your sample. So having that continuous, much more thorough sampling process will help you with marketing,” Folk said.

He said the combine sampler will also help growers produce field maps, including protein and fusarium maps, that will help them improve how they manage their crops.

“Fusarium might be a problem in one area, or it might be a problem across the whole field, but you have no idea right now where that’s happening. So, you can’t even start to manage that problem until you understand where it is,” Folk said.