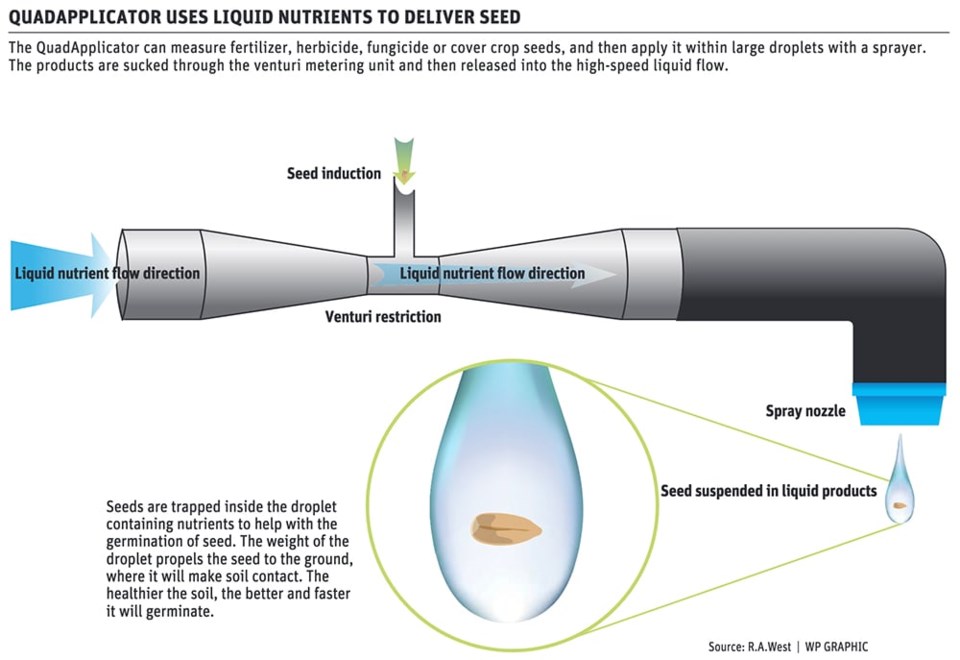

WESTERN PRODUCER — To establish cover crop on fragile land, simply secrete a seed in a mild solution of start-up fertilizer and stabilize the droplet until it sprays out through a number-25 FloodJet nozzle.

It’s actually not that simple, according to the man who is doing it. Bob West, of R.A.West in Vulcan Alta., is ready to launch his new QuadApplicator this spring.

The QuadApplicator earned its name from the fact that it can apply four main liquid products: fertilizer, herbicide, fungicide plus cover crop seeds ensconced in large droplets of prescribed liquid nutrient.

Seeds are sucked through the venturi into the liquid flow as far back as 80 feet from the nozzles. The carrier fluid has a higher specific gravity and viscosity than water, so there’s bigger droplets and less spray drift. Upon impact, these droplets pack the seeds into the soil and cover them with nutrient and moisture.

West said that each individual seed is held by the metering unit until it’s time for it to be released into the high-speed liquid charging through the injection venturi. The goal is to establish one cover plant per sq. foot of surface. He says the technology works for small seeds but is not worth trying on larger seeds.

“We have to be careful to match the seed size to the nozzle size to avoid plugging. We’re looking at seed size of 200,000 seeds per pound, such as alfalfa. There are some seeds that go up to 1.3 million per lb., but we aren’t trying them. Clover will be one of the main cover crops we’ll try at first. That’s about 500,000 seeds per pound.

“We’re using a number-25 FloodJet nozzle. We could go to number- 30, but this seems to be working. It should give us our one plant per sq. foot. We go in with the cover crop applicator just after the herbicide spray.

“Droplet sizes range from 4,000 microns to 300 microns. Ideal droplets would be 600 to 1,000 microns. We’re still doing testing, but that’s hard to do when your PWM pump is just keeping up with the travel speed. Therefore, our size and range are changing a lot. We’re targeting 30 gallons per acre with the products in the tank.”

Although the nuts and bolts of the QuadApplicator are certain to draw attention, West said virtually every component came from the parts department: The Liquid tank, seed metering unit, injector venturi, nozzles, controller and all the plumbing. Some components were modified.

“All these components have been around for years, but nobody put it together. Nobody bothered to connect A to B to C until we did. It took us two years to finally get this thing to work. We figured out that the slurry technology just would not work.”

West said the nutrient package is key to making it work, including humic acid to boost nutrient uptake in plants. The company is soil testing in an organic format of chemistry to determine where nutrient levels should be.

“If we can balance humic acid with formic acid, then we can move. We can’t do anything until we have a grip on the balance. We’re not new to this chemistry. We’ve been doing these experiments and side-by-side trials since 2015. Plus, there are a lot of highly skilled researchers out there who’ve been working on establishing cover crops for a lot of years. We touch base and learn a lot from them. They’ve set the ground work for what we’re done. I think we have a pretty good handle on it now.”

He said that if soil is healthy and nutrition is up to par, then there would be no need to wrap the seed within a nutrient bubble. The QuadApplicator is not intended for healthy soils. It’s intended for depleted fragile soil that has a hard time supporting a cover crop, or any other crop for that matter.

“We have launched a study to document the efficacy of the technology. Success will be measured in three areas: number of seeds germinating, survival rate, improvements to soil health. We’re working with Chinook Applied Research in the study. We need to create a benchmark for the soil health aspect so that we can monitor these ongoing soil conditions.”

There are no unique one-off devices in the machine. All components are off-the-shelf from the R.A. West parts department, so it won’t be hard to produce. If field testing is successful this summer, West said the QuadApplicator could be available for sale this fall.

The Western Producer will do a follow-up story later this year, reporting on results from this summer’s field testing.