REGINA — A control system capable of operating a grain cart tractor remotely was displayed by RCFarmArm during Canada’s Farm Show held June 20-22 in Regina.

The company builds hardware that overlays a tractor controls in the cab, and its initial product is used for remote tractor operations with augers, baggers, extractors and stationary p.t.o. work.

The original RCFarmArm is wireless, yet it enables the operator to remotely control the r.p.m., hydraulics, p.t.o., and the key from outside the cab.

Not tinkering with the CAN bus can help farmers avoid awkward conversations with OEM’s when warranty is needed on the tractor.

RCFarmArm won multiple innovation awards since its launch in 2021, and there must have been demand for it because the business quickly grew out of the workshop in the farmhouse basement near Grande Prairie, Alta.

“We started off with about 10 (3D) printers in the basement, and then I finally kicked him out of there and made him buy a shack. So, he could put the printers out there and he got a bigger printer, and now we have to decide if we’re going to build something else or just add another shack because we just keep outgrowing our spaces,” said Christina Pawluski of RCFarmArm.

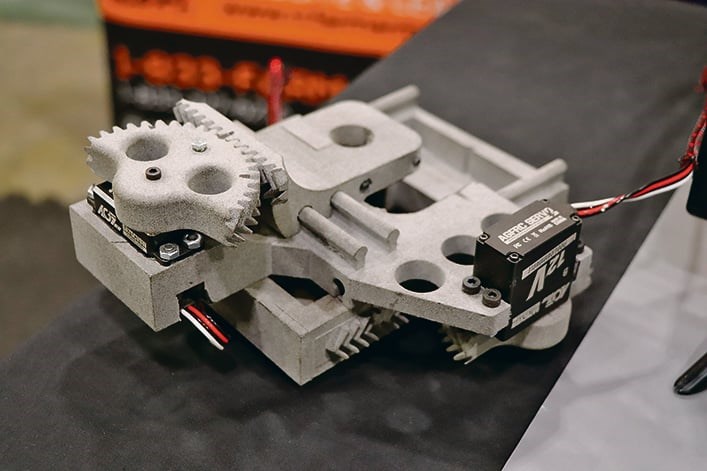

Vincent Pawluski of RCFarmArm said the hardware that overlays the tractor controls is 3-D printed, which he designs by scanning the control surfaces of tractors.

“The RCFarmBot is a remote-control tractor. It’s a stepping stone into autonomy,” Vincent said.

“It’s a proving ground for us, for our technology and our patent, to prove to the software companies that exist right now that we can take their control software and we can put it on any tractor of any age.”

The RCFarmBot can control the steering wheel, clutch, parking brake and gears. So far, the system has been built to fit late model CNHi, John Deere and Versatile tractors.

Vincent said he’s still working on the finishing touches of the remote control, but that it is being designed to mimic the controls in the tractor.

“It has a steering wheel, it has a gearshift, it has a throttle. It’s a visual representation of what’s in a tractor, so it’s not just user friendly, but it’s also user intuitive,” Vincent said.

“The initial use cases for this (RCFarmBot) are grain carts. This remote system is for single combine farms, because you got a guy sitting in a grain cart and he’s running hours for just the air conditioning.”

He said the RCFarmBot will work especially well when the combine operator is using the combine GPS, because they will be hands free and will be able to pick up the controls for the grain cart tractor.

The RCFarmBot can push the GPS button in the grain cart tractor, and Vincent said it’s easy to keep the tractor going straight when unloading the combine.

Once the grain cart is full, it can be positioned where the truck driver can unload it, which will help keep harvest rolling along with only two operators.

Vincent said he’s looking to partner with another software company to manage the bot’s navigation.

“If we could team with another software company that’s already doing that, it would be advantageous for us rather than reinvent everything that they’ve already done,” Vincent said.

This fall there will be three RCFarmBots sold to farmers who plan to use them during harvest.

For safety features, the RCFarmBot hardware locks in place, making it difficult for any tractor control to slip out of position.

The company is also working on placing a camera inside the cab, so operators can see both the tractor gauges and where it’s travelling.

During the research and development stage, the RCFarmBot will retail for about $20,000, and it will sell in the $30,000 to $30,000 range once released commercially.