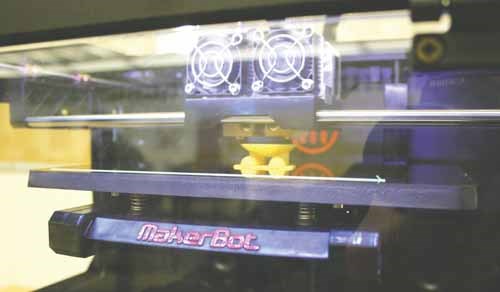

There is a buzz around the drafting classroom at Yorkton Regional High School like never before. Even students who have never even thought about taking the course are popping by to visit drafting teacher Ryley Wawryk and his new MakerBot: Replicator 2X.

Last semester Wawryk started hearing about commercial desktop 3D printers. After doing some research, he realized it would be a perfect addition to his classroom and was surprised to find out how affordable they had become and that there was a dealer selling them in Outlook, Saskatchewan.

He put together a presentation for his department head and got the go ahead to spend the $2,700 as a trial.

Right now, the printer is a bit of a novelty for the student body.

"They're really excited," he said. "I get a lot of kids coming by between classes to talk to me about the 3D printer just to see what it's doing."

What it's doing at the moment, is printing a bunch of novelty items such as Star Wars and Despicable Me action figures while Wawryk and some of his senior students figure out how to use it and calibrate it to print properly. He is giving away the items to students to raise awareness about the technology.

The MakerBot software operates by taking a 3D model and slicing it into layers only a fraction of a millimetre thick. It then sends instructions to the extruders to lay down the layers in molten plastic building the object from the bottom up. The plastic is fed into the extruders from spools of plastic cord. The model at YRHS can print with two colours of plastic at a time.

While MakerBot, the company, is positioning its product to become the Commodore 64 of 3D printing, the Regional's latest purchase is not a toy. Just as the rulers and pencils that used to be the tools of classroom drafting have given way to computers and AutoCAD software, Wawryk envisions a time in the not so distant future that the balsawood and nails they currently use to model their designs will be replaced by a fleet of 3D printers.

"Just because it links up so well with drafting, we can physically make what we draft now, which is unbelievable," he said. "The kids can put it on paper in 2D then print it and hold it in there hands and see exactly what they made."

While he still has some tinkering to do to get the replicator to print at the optimal speed and get it working with AutoCAD files, Wawryk said his classes in the coming semester will be using it for class projects. The first one he has planned is for students to draft and make themselves cases for their cell phones.

He said the people at Thorstad Computers in Outlook, where he got the printer, have been extremely helpful.

"They've been wonderful to work with," he said.

Although the technology is still not quite at a price point that will see 3D printers in every home, Wawryk believes it is important for the kids he is teaching to get accustomed the technology now.

"This way, if they can make them on AutoCAD and transfer the file to 3D print them, it's the next generation, I think, of doing everything," he said.

.png;w=120;h=80;mode=crop)