Saskatoon– Petroleum scientist Ian Gates relies on the humble soda bottle to explain the huge issue of foamy oil.

“It’s just like when you open a Coke bottle…the bubbles come out,” said Gates, head of Chemical and Petroleum Engineering at the Schulich School of Engineering, University of Calgary.

“We open (an oil) reservoir, the bubbles come out. The bubbles are really small, and because they remain small, they form this foam.”

He goes on to explain that the process of cold heavy oil production with sand (CHOPS) leaves gaps, or wormholes, in the reservoir, which create a drop in pressure. Similar to a can of shaving cream, the foam then arises from natural gas mixing with oil as the well depressurizes.

“Foam has low viscosity. As you produce it, you produce the finely-grained sand. It depressurizes (the well) and stops. It’s stuck. There’s no more energy to get it out. You’re looking at getting 10 per cent of oil out of the reservoir.”

Remarkably, after decades of oil extraction, no one really understands why this foaming happens in CHOPS. What Gates does know is that foam plus sand equals low recovery, and he is determined to change that, with help from a new collaborative research project.

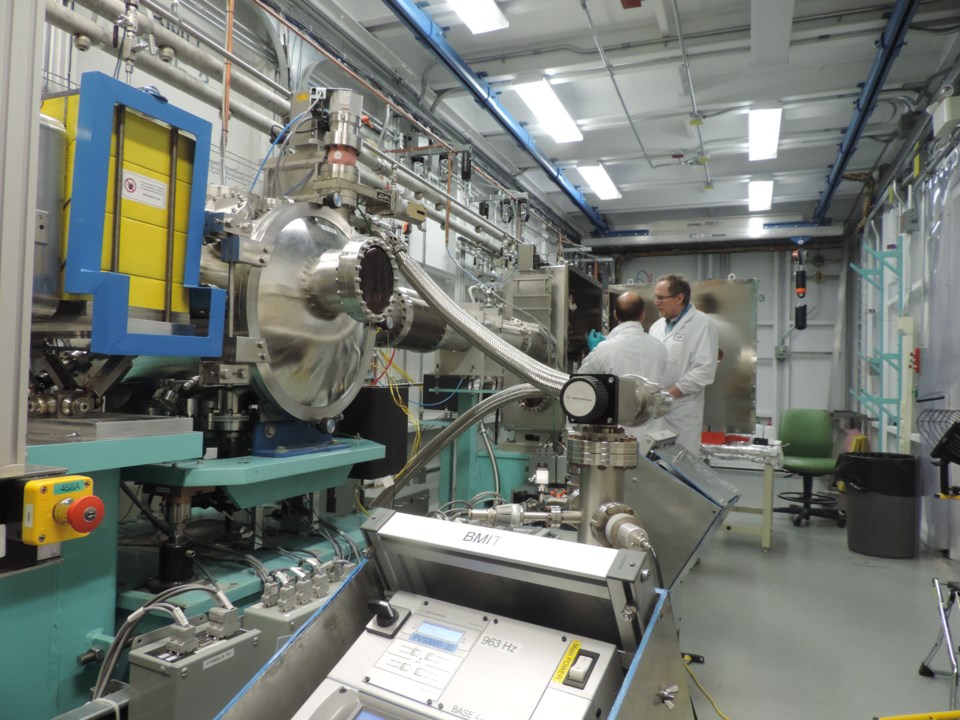

His new weapon in the search for a better oil recovery system is a powerful beam of light. The light comes from the Canadian Light Source (CLS) Synchrotron on the University of Saskatchewan campus in Saskatoon. Funding for the research was announced Nov. 20 at a news conference held on a platform in the middle of the scientific facility.

Innovation Saskatchewan is providing $160,000 for the project, with $100,000 coming from the Petroleum Technology Research Centre (PTRC) in Regina. The CLS and the University of Calgary are providing in-kind support, bringing the project’s total cost to $303,000.

The scientific team will build a miniature reservoir containing oil, gas and water, and put it in a beamline at the CLS Synchrotron. The synchrotron’s beam is created by using radio-frequency waves and magnets to accelerate electrons close to the speed of light within a massive ring. Beamlines come off the ring, and produce a variety of light wavelengths that can “see” matter at the molecular level.

“As the X-rays go through (the reservoir) we’ll see the bubbles, we’ll see how they evolve, how the sand grains move, and then as we add the additives we can see, ‘Oh, this is what this did,’” said Gates.

Gates thinks a polymer or a carbon dioxide additive may assist in cold heavy oil recovery, but the team first must do detailed experiments to make sure their ideas actually work in reality.

The research reservoir is only eight inches long by about an inch in diameter. If the scientists can figure out the foaming mechanism, they will scale up the experiment to a larger reservoir, and hopefully bring it to field trial sometime in the future.

“After decades of production, we can finally understand what’s going on,” said Gates.

“When you look at the economic value…even two per cent, from 10 to 12 per cent, you’re looking at billions of dollars of income,” Gates added. “Not just millions, billions. What we’re going to try to do is increment it by looking at how does the foam form? How do we elongate (the well’s) life? It’s not clear to us yet, but if we can improve how we understand it, we can then do the design work to basically manage it. And in managing it, we can hopefully extend the life (of a well.)”

In Saskatchewan and Alberta, there are tens of thousands of wells sitting idle that have produced the 10 per cent, “and we don’t know what to do with them,” said Gates. “And we don’t abandon them, because all the companies are thinking a follow-up process will arrive.”

Ken From, CEO of the PTRC, said the research project is a potential game-changer and extremely important in a low price oil environment, such as the one hurting the industry today.

“What typically happens is people really cut back on their capital expenditures,” said From in an interview. “When you cut back on your capital, how can you increase or maintain your oil production? Well, that can come from your existing wells. You don’t have to drill any more; you’re not adding to any environmental footprint; your (capital expenditure) is way down.

“Enhanced oil recovery is, in many people’s opinion, the most economic way of producing that incremental oil. In periods of low prices, enhanced oil recovery becomes more important.

“What is challenging, though, is funding to do the research because prices of oil are low. It’s that Catch-22. If you’re a large company you can afford that; if you’re a smaller company, you might be a late adopter for the technology that comes out of the research. It’s almost counter-intuitive that when prices are low, that’s when you want to do the most research.”

In Saskatchewan, heavy oil makes up 55 per cent of production, making it the largest contributor to the province’s industry.

From noted that companies using thermal techniques can heat oil and improve its viscosity through SAGD – steam assisted gravity drainage. However, with CHOPS, there is no thermal element to production.

“It is not expensive, but when you’re producing it cold, you can’t really get as much out,” he added.

“We have a particular problem with our cold wells, in that the sand is not consolidated; it’s not like a rock. Those sand grains will move. As the oil comes out, it’s like foam. That foam…traps the sand.

“These things stop at about somewhere between five and 10 per cent of oil production. The question is, how do we get more out?”

The experiment will take place on the CLS beamline called BMIT, short for Biomedical Imaging and Therapy. While that may seem counter-intuitive, since oil foam is not biomedical, the line provides three-dimensional imaging that will be useful to this experiment.

The project marks a first for the CLS, as well. It’s the first time a synchrotron has been used to visualize a heavy oil system.

“We are pleased to invest in this project that has the potential to increase oil production in heavy oil reserves with very little investment in new equipment,” said Jeremy Harrison, Saskatchewan’s minister responsible for innovation.

Continued research is key to the long-term viability of the province’s oil and gas industry, he added