Calgary – The dirt did it. More specifically, wet dirt did it. The much-anticipated engineering reports explaining the cause of the July 21 Husky pipeline oil spill north of Maidstone which then flowed into the North Saskatchewan River cited ground movement, caused by rain, as the culprit.

That spill, of approximately 225 cubic metres (1415 barrels) of blended heavy oil and condensate, contaminated the primary fresh drinking water source for several major communities along the North Saskatchewan River, including North Battleford, Prince Albert and Melfort. Those communities scrambled to put into place alternative water sources. North Battleford relied on its groundwater treatment plant and eventually additional water from the Town of Battleford. Prince Albert built an overland water pipeline, essentially a large hose, from the South Saskatchewan River. Melfort put an old water reservoir back into service. By mid-September the all clear was given and Melfort and Prince Albert began drawing on North Saskatchewan River water again.

On Nov. 17, Husky Energy Inc.’s two reports were released by the Ministry of the Economy. Those reports, initially required by Oct. 21, were granted an extension of 30 days by the Ministry. The pipeline metallurgical failure analysis report, by engineering firm Acuren Group Inc., was dated Oct. 24, 2016, while the geotechnical investigation Report, by engineering firm Stantec Consulting Ltd., was dated Nov. 3, 2016.

In its report submitted to the Ministry, Husky said it had completed a thorough investigation into the 16TAN pipeline incident and submitted its report to regulators. (“16TAN” is Husky’s name for the pipeline). The report addresses the cause of the incident and identifies actions to prevent a similar incident, Husky added. “The investigation was informed by reviews conducted by internal and external experts covering the following areas: metallurgical, geotechnical, pipeline integrity, leak detection system performance and operator response.

“Stantec Consulting’s geotechnical report, filed on IRIS (Integrated Resource Information System), has concluded that the pipeline break was the result of geotechnical activity (ground movement). Acuren Group’s metallurgical report, filed on IRIS, has concluded that the break was a sudden, one‐time event in a section of the pipe that had buckled due to the force of ground movement. Its report also concluded the break was not the result of material defects, deficiencies or corrosion.”

Based on its findings, Husky is moving forward with a number of immediate actions while regulators continue with their review.

Actions

In their report to the Ministry of Economy, Husky noted, “While the investigation has concluded the Saskatchewan Gathering System was designed and constructed in accordance with applicable standards and operators responded appropriately, Husky is implementing improvements to the systems and operating procedures.”

Those actions include ensuring geotechnical risks are addressed and re‐assessed over the life of a pipeline with mitigation and monitoring strategies. This would include route selection, design consideration for stress relief through excavation, and additional monitoring technologies such as inclinometers. Husky will also work on application of additional safety loading factors to locations which are susceptible to potential geotechnical risk, which would increase the force that could be exerted on the pipeline. Husky is reviewing and consolidating existing leak detection processes and procedures. Improvements will include a defined time period for diagnostic analysis before proceeding to a mandatory shutdown. Finally, Husky is adjusting variables on the leak detection systems to reduce the number of false alarms.

Severe buckling

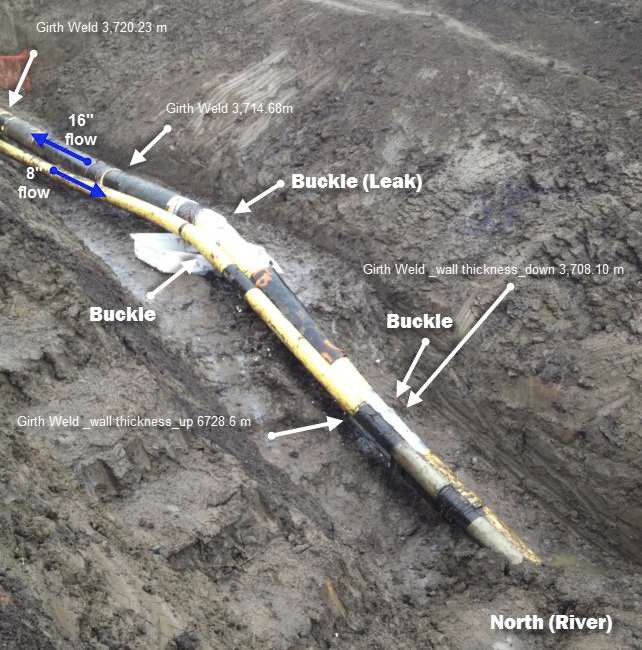

The 16 inch pipe buckled, with the bottom of the pipe bulging and splitting, as indicated by numerous photographs in the pipeline metallurgical failure analysis report conducted by engineering firm Acuren and written by Brian Wilson, M.Eng., P.Eng. senior materials engineer.

The report concluded, “Based on the findings of this investigation, it is Acuren’s opinion that the submitted nominal 406.4 mm OD by 7.9 mm WT pipeline sample failed as a result of localized severe buckling deformation in the bottom half of the line, followed by brittle cracking on the ID surface of the pipe at the apex of the buckle and subsequent ductile overload fracture from these brittle cracks, resulting in a through-wall fracture within the buckle. There was no evidence of a progressive time-dependent cracking mechanism (e.g. fatigue) associated with the brittle fracture. The timing of the original buckling of the pipe could not be determined in our investigation and determination of the source(s) and nature of the applied loading conditions on the pipeline necessary to cause this buckling and the subsequent cracking within the buckle were beyond the scope of this metallurgical failure analysis.

“There was no evidence found to indicate that substandard pipe material or corrosion contributed to the failure.”

The 16 inch pipeline, built in 1997, was operating at 5,550 kiloPascals pressure, at a temperature of 53 C. It was transporting 273 cubic metres per hour (1,717 barrels per hour or 41,208 barrels per day) of blended crude oil.

The metallurgical report noted, “The line was understood to have been pigged on a monthly basis and was being continuously treated with Cortron RU-166 corrosion inhibitor and batch treated with Bactron K-48 biocide. The outside surface of the pipe was reportedly covered with Yellow Jacket YJ2 extruded polyethylene coating, overlaid with polyurethane foam insulation, which in turn was covered with a black polyethylene outer coating. There has reportedly been five in-line inspections performed on this line over its history, with the most recent ILI being in January 2015. There have reportedly been no previous failures associated with this pipeline.”

The pipeline deflected approximately 21 degrees, centred on the buckle.

“The external surface of the pipe, including the buckled zone, did not exhibit any evidence of corrosion damage,” Acruen said.

Second pipe

What was not mentioned in previous statements is that there was in fact a second pipeline in the same ditch, an eight inch pipeline whose flow was in the opposite direction of the 16 inch line that leaked. A figure in the metallurgical report indicated the second pipe, immediately adjacent to the larger one, bucked at nearly the exact same spot. However, it did not leak. That eight-inch line transported condensate.

“This condensate line also exhibited buckling deformation at approximately the same location as the buckled leak site in the 16TAN line. Samples were also cut from the non-failed buckled locations of these two pipelines and submitted to Acuren for examination and testing,” the Acuren report said. Results of the have been addressed in a supplemental Acuren report to Husky.

Geotechnical report

Stantec’s report on the geotechnical causes of the ground movement cited high precipitation as the ultimate culprit, saying, “Given the available data to date, the more recent movement affecting the pipelines was likely triggered by a high precipitation event, surface topography that impedes drainage and the weak pre-sheared foundation of Cretaceous clay shales,” it said.

The report didn’t leave a lot of options for actions to prevent further ground movement in the future. This report was authored by Carrie Murray, M.Eng., P.Eng,, senior geotechnical engineer, and Richard Guthrie, M.Sc., PhD, P. Geo., director of geohazards with Stantec.

“Remedial stabilization measures were considered infeasible given the large size and complexity of the landslide, the report noted, citing the size of the valley in question. The south slop is 104 metres high, from the top of the valley to the water’s edge. The horizontal length is 1080 metres, giving an average slope of 10:1, or 5.5 degrees slope inclination.

“Slope modifications such as slop re-grading or removal of soil loads at/near the top of the slope are not recommended given the scale of the slope and considering that small disturbances to the slope may initiate further movement,” the Stantec report said.

Similarly, buttressing the toe of the slope with a toe berm or retaining structure is not practical, as it would require multiple tiers and would need to the extend some distance both east and west of the pipeline corridor, at very significant cost.

Dewatering the slope is not likely feasible due to the nature of the clay shale present.

Thus, monitoring slope movements to manage pipeline integrity risk and implementing mitigating design measures as necessary are suggested.

On the other side of the river, the north slope has no open ground cracks along the pipeline alignment, but an open ground crack was observed 100 to 300 metres east of the pipeline alignment. Not pipeline integrity issues have been reported along the north slope, but the reports recommends future monitoring be undertaken along with monitoring of the south slope.

Minister responds

Minister of Energy and Resource Dustin Duncan spoke to reporters in the Legislature on Nov. 17. He pointed out the Ministry had just received the report. “We’ll have to take some time to look at it as part of the ongoing investigation that the Ministry is conducting. Again, I want to stress this isn’t our final report, this is just Husky’s final report on the incident. It’s an important part of the ongoing report the Ministry is conducting, but the Ministry’s work still continues.”

“The conclusion that is drawn in the report, in terms that ground movement was the cause of the breach of the line, is consistent with the ministry officials that are part of the investigation. It’s consistent with our findings to date,” he said, adding the Ministry’s report is not yet complete, and could say something different.

The Ministry has been in contact with other pipeline operators to look at their programs and ensure there isn’t a risk of other pipelines doing this.

“We’re going to have to look at, as a part of not only the outcome of this report, but going forward, what we need to do, if anything, to give assurances to the public there aren’t further risks out there, going forward,” Duncan said.

Duncan anticipates the Ministry’s report will be done in early 2017.

Asked about potential charges, Duncan said once the Ministry’s final report was complete, they would be in a better position to speak about consequences for Husky. Ministry staff are working on the report, with the assistance of a third party engineering firm, SkyStone International.

As of Nov. 21, Husky’s web page, www.huskyenergy.com, no longer carried a direct link to their spill response page. The companys news web page references have been limited to the following, “Shoreline cleanup operations on the North Saskatchewan River have been completed. Monitoring activities will continue through the winter and into 2017.

“We would like to acknowledge the extraordinary assistance of communities and First Nations.

“A toll-free line will be monitored regularly so as to assist with any further inquiries. The number is 1-877-262-2111.”

The press releases dated since July 21 currently listed do not include references to the spill.

In an emailed statement, Husky spokesperson Mel Duvall said, “We know the impact this incident had on communities and would like to acknowledge the extraordinary assistance we’ve received throughout. From the beginning we have taken full responsibility and continue to do so.

“Based on our findings, we are moving forward with a number of immediate actions while regulators continue with their review. While the investigation has concluded the pipeline was designed and constructed in accordance with applicable standards and operators responded appropriately, it is our intention to use these findings to further enhance our systems.

“Our overall objective is to continuously improve the integrity of our systems and operations.”