Lloydminster - Rob Morgan, COO of Crew Energy, in his keynote speech to the Lloydminster Heavy Oil show banquet, spoke about the importance of technological advancement to continued development of heavy oil in the Lloydminster region. That is exactly the strategy PCM is taking, according to Rob Heffner, CEO for PCM Canada Inc., as it develop cost effective and innovative solutions for the next step in thermal heavy oil development.

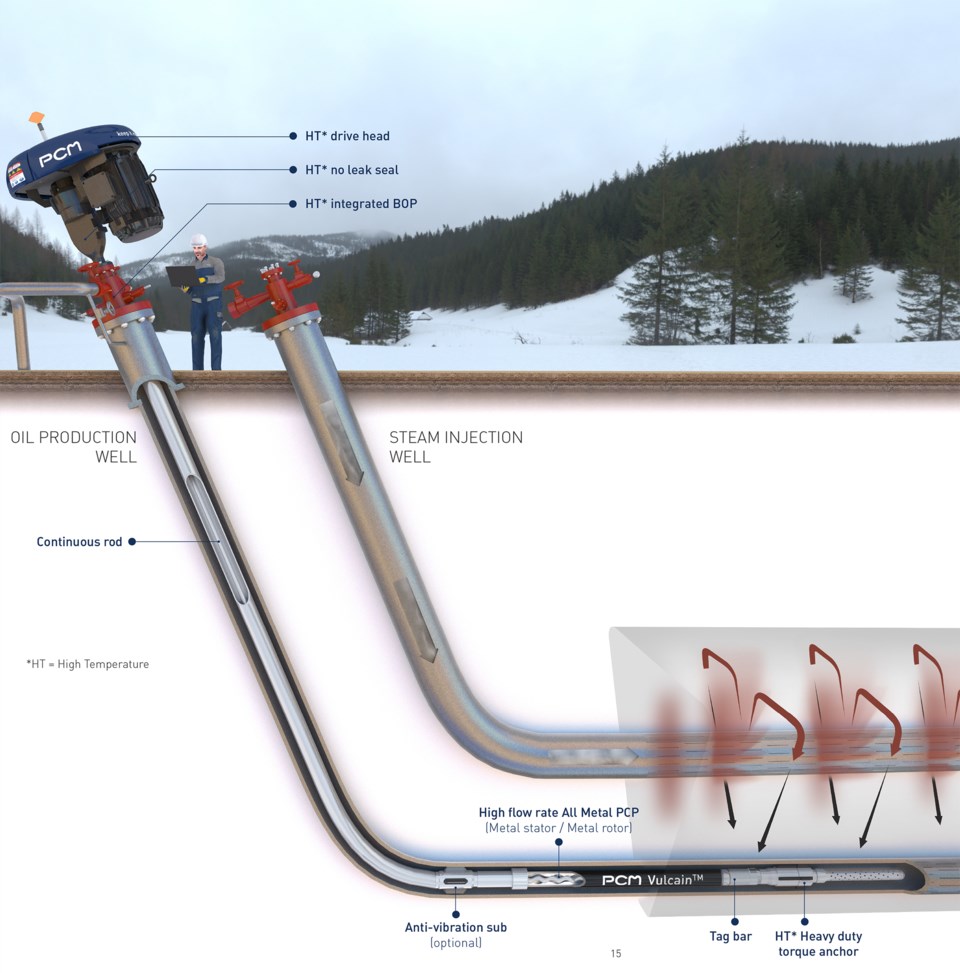

A decade ago, the company was first to introduced the metal to metal pcp with the patented PCM Vulcain for applications in high temperature thermal extraction plays like steam-assisted gravity drainage (SAGD).

Progressive cavity (PC) pumps have dominated the heavy oil play around Lloydminster for three decades now, largely due to their ability to handle solids, i.e. sand. However, typically reciprocating pumps are used for thermal plays, as the rubber elastomer that makes up the stator portion of the PC pumps can’t take the intense heat. The PCM Vulcain is meant to deal with those environments.

Robert Heffner is the CEO for PCM Canada Inc., based in Lloydminster. It’s part of PCM Group, headquarters based in France. PCM has locations in Edmonton and Bonnyville.

“I’ve been in the industry for 37 years,” Heffner said. He was a tradesperson initially, as a millwright. He started in the oilpatch in 1980 and worked for Husky from 1985 to 1996. At age 36 he became vice president of Corlac Industries, a position he held for eight years. That included manufacturing of artificial lift, wellhead drives and packaging of PC pumps.

Two-thirds of Corlac, the artificial lift business, was purchased by NOV in November 2003, and that’s where Heffner ended up for two years as general manager.

In 2006 he started AMIK Oilfield Equipment and Rentals Ltd. He was president and major shareholder. In December 2014 he sold 75 per cent to PCM SA out of France, staying CEO for the Canadian operations for the last two years.

PCM’s display at the Lloydminster Heavy Oil Show on Sept. 14-15 showed a large variety of artificial lift technologies, including hydraulic jack, cable jack, PC pump wellhead drive, and a horizontal pumping system.

“We’re diversified in artificial lift. As producers turn to new technologies, we are steadily trying to improve what we have to offer to the industry to keep us sustainable in a low commodity price of oil,” Heffner said, adding that service has carried the company in recent years.

The metal-to-metal PC pump was the highlight of their display. But Heffner noted PCM was started in the 1930s. “From PCM’s early beginning with company founder and French engineer René Moineau, who also invented the elastomer progressing cavity pump, to the present day, pioneering and innovation has always been part of the company DNA.”

“Introduced in the mid-1980s, the PC pump is what saved heavy oil. From the ’90s to present, it’s been the number one pump of choice to get cold heavy oil production out of the ground, better known as CHOPS (cold heavy oil production with sand),” Heffner said.

A PC pump can handle up to 50 per cent solids, he noted. But in thermal, screens are used to block sand.

“With thermal, you don’t bring the sand to surface. You hold it back in the reservoir through screen placement in the horizontal section of the wellbore,” he said. The sand volume is reduced to less than one per cent.

Looking ahead, SAGD is where it’s at. Husky indicated as much several years ago, when the company signalled a substantial shift to thermal. Heffner said, “Going to the future, what’s revolutionized the industry is SAGD.”

“That technology recovers up to 80 per cent of the oil reservoir, as opposed to the average 10 per cent, with CHOPS. With PCP, and most wellbores you can get roughly 10 per cent of recovery with primary production – cold heavy production, with no secondary recovery.”

Waterflood can improve that number quite a bit, but it’s also costly to move that much water around, he noted.

“For the big players … thermal is the way of the future,” he said. “Over the past 10 years, PCM has deployed its metal-to-metal pump in more than 11 countries. Today it is in production in Fort McMurray area and there are 100 pumps producing in northern Alberta today, with one company starting up 38 metal-to-metal pumps this fall.”

“We also have the wellhead drive with a new, innovative and patented stuffing box design that will control leakage and spills. It will be going out on test here in the next month,” he said.

“We overcome the wellbore pressure with a cooling, lubricating fluid. We over-pressurized the stuffing box so that if any debris enters the packing, it will be flushed out. The key to the stuffing box is we over-pressurize the well so no contaminants can enter it. We lubricate it 24/7, and it’s managed by itself. It’s worked well. It’s been working well in primarily CHOPS well. We’ve got one running on test for nine years that still hasn’t failed. Our second prototype of our gear well-head drive, has eight years without a drop of oil to the ground.”

This has been developed into the new PCM B-100 thermal wellhead drive which will be launched locally this fall.

“Where the industry and pricing is, being very down, like Rob Morgan said last night in his speech, heavy oil (businesses) have to find the next technology to advance heavy oil. I believe it is thermal. The recovery of the reservoir is up to 80 per cent with SAGD technology.

“We’re excited about it, as we look to the future,” Heffner said.